Manufacturing Process

Final Batching and Testing

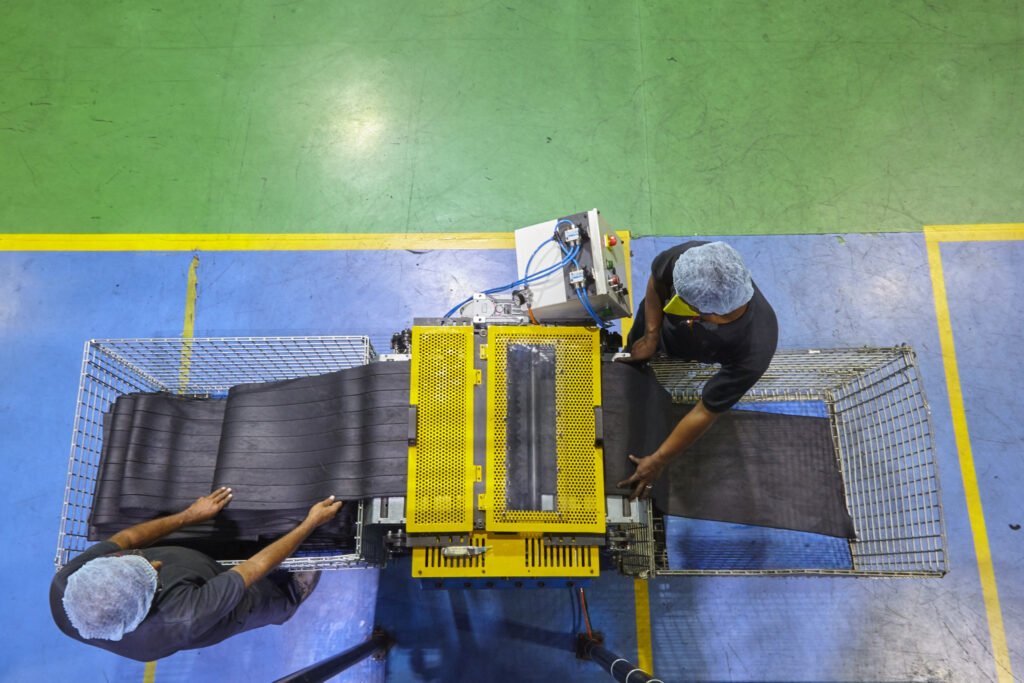

For this process, we use an advanced intermixing system and a robust stock blending unit to ensure our rubber compound is perfectly mixed. After blending, the final batch-off system cools the rubber to room temperature through efficient atomization. This cooling phase allows the chemicals to settle properly. Subsequently, the rubber is expertly cut into sheets or strips to meet specific customer requirements, reflecting our commitment to high-quality, tailored solutions.

Straining

We offer in-house straining to meet customers’ specific needs for rubber components in critical applications. Using a gear pump extruder, we filter and purify the rubber compound, ensuring top-quality standards and purity.

Testing Laboratory

We have the below testing equipment to facilitate and validate our rubber compounds.

End To End Traceability

With our advanced barcoding system, we ensure end-to-end traceability, tracking every rubber batch from Mixing to Dispatch. Our unique batch numbers provide full transparency and accountability, reflecting our commitment to high standards and precision.