SBR Rubber Solutions

Proven Durability, Built for Performance

At GB Gummi, we specialize in delivering durable, versatile, and high-performance rubber solutions tailored for industrial and commercial applications. Among our key offerings is Styrene Butadiene Rubber (SBR), a synthetic elastomer derived from styrene and butadiene, trusted worldwide for its reliability and cost efficiency.

Originally developed in Germany in 1929 as a substitute for natural rubber, SBR played a pivotal role during World War II, with mass production in the United States compensating for disrupted natural rubber supplies. Its legacy of resilience continues today, making SBR one of the most widely used rubber compounds globally.

Renowned for its abrasion resistance, tensile strength, and affordability, SBR is the preferred material for a wide range of products, including automotive tires, industrial seals, footwear, belts, and more. It closely mimics the properties of natural rubber while offering improved consistency and value, making it an ideal choice for high-demand environments.

Whether you’re building for performance, endurance, or economy, our precision-compounded SBR solutions deliver dependable results every time.

Properties of SBR rubber

Styrene Butadiene Rubber (SBR) is engineered for performance across a wide range of demanding applications. With enhanced tensile strength, abrasion resistance, and excellent blend compatibility, SBR offers key advantages over alternatives like polybutadiene rubber. It closely mirrors the properties of natural rubber (NR) while providing added benefits in cost-efficiency and formulation stability. Though SBR rubber may have slightly lower gum tensile strength, hot tear resistance, and elongation at break, these can be managed through modern compounding techniques.

Other performance highlights include:

With the right resins, fillers, and additives, SBR’s mechanical and thermal limitations can be significantly enhanced, making it a highly adaptable choice for diverse rubber engineering needs.

What are the different types of SBR rubber?

Styrene Butadiene Rubber (SBR) is available in multiple grades, each designed to meet specific industrial requirements. The performance of SBR can vary depending on the production process, molecular structure, and additives used, offering flexibility in both formulation and application.

Emulsion SBR (E-SBR)

This SBR compound is produced via emulsion polymerization. E-SBR is the most common form of SBR. It is widely used in car tires, footwear, conveyor belts, gaskets, and general-purpose molded goods. Known for its good abrasion resistance, processability, and cost-efficiency, E-SBR is ideal for high-volume applications.

Solution SBR (S-SBR)

S-SBR is a solution polymerization-manufactured material that has superior aging qualities, increased wet traction, and improved rolling resistance. Premium car tires and high-performance rubber goods, where durability and fuel economy are crucial, frequently employ it.

Oil-Extended SBR

This variation improves flexibility, workability, and cost management by adding processing oil during polymerization. It is especially helpful in vibration-damping components, rubber hoses, and tire treads where processing ease and softness are crucial.

Advantages and benefits of SBR rubber

- Styrene Butadiene Rubber (SBR) has earned its place as one of the most widely used synthetic rubbers across industries. Known for its cost-efficiency, balanced performance, and high adaptability, SBR rubber is a go-to material for manufacturers seeking durability without compromise.

- Here’s why SBR stands out:

- Excellent abrasion resistance for high-friction applications

- High tensile strength for load-bearing durability

- Good aging stability with proper additives

- Exceptional blend compatibility with other elastomers

- Cost-effective without compromising performance

- Improved heat and crack resistance

- Consistent processability for complex shapes and designs

Applications of SBR Rubber

- One of the most popular synthetic rubbers in the world, styrene-butadiene rubber (SBR) is prized for its affordability, processability, and longevity. Because of its adaptability, it is a perfect material for many different sectors.

- Common Applications of SBR Include:

- Automotive Tires – Used in treads and sidewalls for abrasion resistance and flexibility

- Footwear Soles – Ensures grip, cushioning, and durability in casual and industrial shoes.

- Conveyor Belts & Hoses – Resists wear and pressure in heavy-duty industrial operations.

- Rubber Mats & Flooring – Provides anti-slip and shock-absorbing surfaces for safe use.

- Seals, Gaskets & Mounts – Offers reliable sealing and vibration-damping in machinery.

- Wire & Cable Insulation – Delivers insulation and weather resistance for wiring systems.

- Adhesives & Coatings – Serves as a base for pressure-sensitive and protective finishes.

What is SBR rubber used for?

SBR (Styrene Butadiene Rubber) is widely used across industries due to its excellent abrasion resistance, flexibility, and cost-effectiveness. It is a key material in automotive tires, where it enhances tread durability and performance. SBR is also used in footwear soles for added grip and comfort and in industrial products like conveyor belts, hoses, and gaskets that demand resilience under pressure. Its insulating properties make it suitable for wire and cable coatings, while its bonding strength supports adhesives and sealants.

Thanks to its versatility, SBR continues to be a preferred choice for both high-volume manufacturing and specialized rubber applications.

Automotive Tires

Used in treads and sidewalls for abrasion resistance and flexibility

What makes SBR rubber unique?

SBR rubber is unique because it can combine affordability, flexibility, and durability into a single composition. SBR offers improved abrasion resistance and reliable performance while closely resembling the characteristics of natural rubber, in contrast to many synthetic rubbers. It is quite versatile for unique formulations since it combines easily with various materials.

It is perfect for high-volume, industrial-grade applications ranging from tires and seals to floors and adhesives because of its resistance to wear and aging (with additives) and ease of processing. SBR stands out for its performance and value balance.

Why use SBR rubber?

SBR rubber is a widely preferred material across industries due to its well-balanced mechanical properties, cost efficiency, and ease of processing. It is perfect for demanding applications like tires, seals, and industrial hoses because it offers exceptional abrasion resistance, high tensile strength, and dependable performance under pressure. Because SBR is compatible with fillers and other rubbers, customized formulations can be made to meet particular needs.

Although it might not be as resistant to heat and tearing as natural rubber, these drawbacks can be successfully addressed using reinforcements and additives. It is a sensible and cost-effective option for manufacturers all over the world due to its adaptability, production scalability, and longevity.

Key Reasons to Use SBR Rubber:

- SBR compound has excellent abrasion and wear resistance

- High tensile strength and durability

- Cost-effective for large-scale production

- Good blend compatibility with other rubbers

- Easily moldable for complex components

- Performs well in industrial and automotive applications

- Properties can be enhanced with additives and fillers

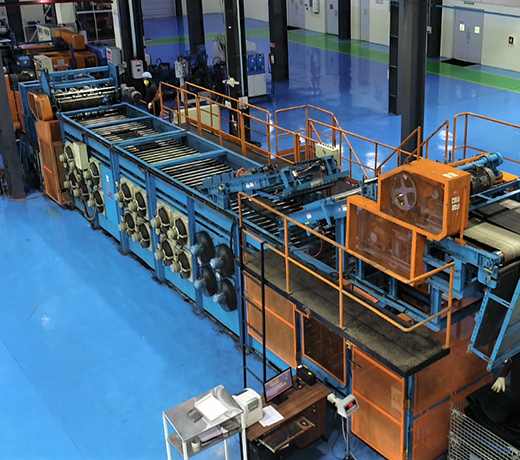

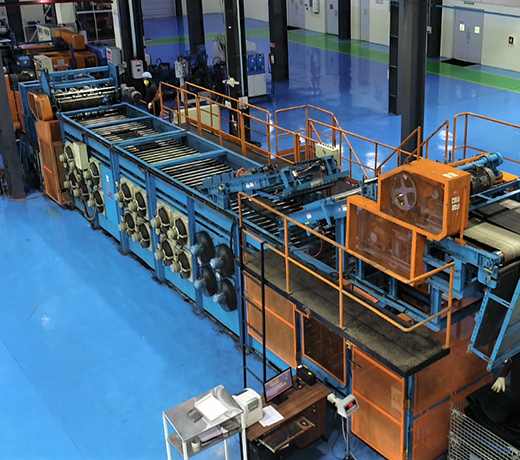

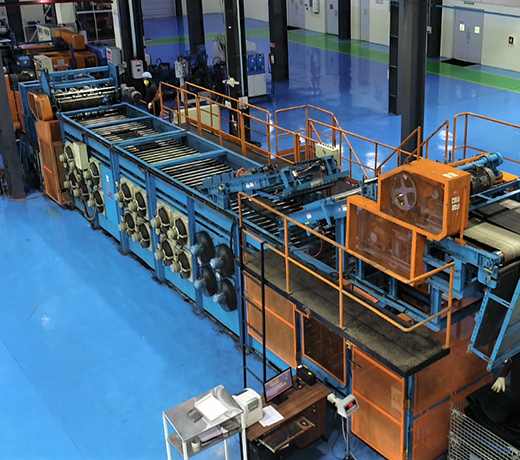

Why Choose GB Gummi for SBR rubber?

Styrene butadiene rubber (SBR) is a smart choice for manufacturers seeking a cost-effective material that offers reliable abrasion resistance, flexibility, and tensile strength. Whether used in tires, gaskets, footwear, or industrial components, SBR delivers performance and versatility across demanding environments. But to truly unlock the potential of SBR, you need the right partner.

At GB Gummi, we don’t just supply rubber; we engineer solutions. Our team of experts understands how to fine-tune SBR compounds to match your exact application needs. With advanced manufacturing capabilities, stringent quality control, and a commitment to innovation, we deliver consistent, high-performance rubber that meets global standards. From custom formulations to technical support, we ensure every batch adds value to your process and product. Choose GB Gummi, where the material meets mastery.

FAQ's

1. What is Styrene-Butadiene Rubber (SBR)?

Styrene Butadiene Rubber (SBR) is a synthetic elastomer made by copolymerizing styrene and butadiene. It is known for excellent abrasion resistance, good aging stability, and cost-effectiveness, making it one of the most widely used rubbers globally. GB Gummi produces high-quality SBR compounds designed for automotive, industrial, and consumer products, ensuring durability and performance while meeting strict international standards for consistency and reliability.

2. What are common products made from SBR?

Common products made from styrene butadiene rubber (SBR) include car tires, conveyor belts, footwear soles, hoses, and seals. Its abrasion resistance and flexibility make it ideal for heavy-duty and high-wear applications. GB Gummi supplies customized SBR compounds that deliver dependable performance, helping manufacturers in automotive, industrial, and consumer sectors create long-lasting, cost-effective products suited for demanding environments.

3. Is SBR compound suitable for automotive applications?

Yes, SBR compound is highly suitable for automotive applications due to its abrasion resistance, flexibility, and cost-effectiveness. It is commonly used in tires, seals, and vibration-damping components. GB Gummi manufactures specialized SBR compounds that meet stringent automotive industry requirements, ensuring durability and consistent performance. Their advanced compounding techniques make SBR a reliable choice for automotive manufacturers seeking both quality and value.

4. Who manufactures SBR compounds in India?

Several companies in India produce SBR compounds, with GB Gummi standing out as a leading manufacturer. Known for advanced technology, global certifications, and tailored formulations, GB Gummi supplies SBR compounds to automotive, industrial, and consumer goods sectors. Their expertise in custom compounding ensures reliable performance across diverse applications, making them one of the most trusted names in SBR compound manufacturing in India.

5. What are the advantages of using SBR compounds?

An SBR compound offers advantages such as excellent abrasion resistance, cost-effectiveness, and reliable performance in high-wear applications. They also provide good aging stability, making them suitable for both industrial and consumer products. GB Gummi formulates SBR compounds that maximize these benefits, ensuring durability and consistency for customers in automotive, industrial, and construction sectors. This versatility makes SBR a popular choice across multiple industries worldwide.

6. Where does SBR rubber come from?

SBR rubber, or Styrene-Butadiene Rubber, is a synthetic material produced by polymerizing styrene and butadiene. Unlike natural rubber, which is harvested from rubber trees, SBR is created through industrial chemical processes, ensuring consistency and availability. GB Gummi manufactures high-quality SBR rubber compounds tailored for automotive, industrial, and consumer applications, delivering reliable performance with excellent abrasion resistance and durability.

7.What are the main properties of SBR rubber?

The main properties of SBR rubber include excellent abrasion resistance, good tensile strength, and cost-effectiveness. It also provides reliable performance in dynamic applications, though it has moderate resistance to heat and aging compared to other rubbers. GB Gummi develops SBR rubber compounds that optimize these properties, ensuring durability and flexibility for industries such as automotive, footwear, and construction where strength and affordability are critical.

8. What are SBR used for?

SBR, or Styrene-Butadiene Rubber, is widely used in car tires, conveyor belts, footwear, seals, hoses, and industrial products. Its abrasion resistance and cost-effectiveness make it ideal for high-wear applications. GB Gummi supplies tailored SBR compounds to meet diverse industry needs, ensuring consistent performance and durability. This versatility has made SBR one of the most popular synthetic rubbers in global markets.

9. How is SBR different from natural rubber?

SBR differs from natural rubber in its origin and properties. While natural rubber is harvested from rubber trees, SBR is synthetically produced by polymerizing styrene and butadiene. SBR provides excellent abrasion resistance and uniform quality, while natural rubber offers higher elasticity and resilience. GB Gummi formulates both natural and SBR compounds, helping industries choose the most suitable material for their specific performance requirements.

10. What are the future trends and advancements in SBR rubber technology?

Future trends in SBR rubber technology include eco-friendly production, improved recyclability, and advanced compounding methods for greater durability and performance. Innovations focus on reducing environmental impact while enhancing resistance to heat, wear, and chemicals. GB Gummi stays ahead by investing in advanced R&D and sustainable practices, offering SBR solutions that align with evolving global standards and customer demands for greener, high-performance materials.

We Deliver Custom Rubber Compounds for Every Need

Contact Us For Professional Support And Guidance.