Neoprene

The All-Weather Synthetic Rubber for Modern Industries

Neoprene, a synthetic rubber that is renowned for its exceptional resistance to weathering, chemicals, oils, and temperature fluctuations, is one of our most durable and adaptable products.

Neoprene, commonly referred to as polychloroprene, was first developed as an alternative to natural rubber and has since become essential in various sectors, including the automotive, aerospace, marine, and medical industries. In damp and chemically exposed settings, where long-term performance, durability, and insulation are crucial, Neoprene outperforms materials like Styrene Butadiene Rubber (SBR).

Neoprene’s special qualities make it the preferred material for applications requiring durability under strain, whether you’re producing wetsuits, industrial seals, or protective gear.

Properties of Neoprene

Neoprene is known for its remarkable resilience to environmental influences and degradation. It is a high-performance material for both commercial and industrial applications because of its polymer structure, which enables it to function reliably under harsh conditions, including high temperatures, corrosive environments, and extended exposure to oils and sunlight.

Key properties of Neoprene include:

Types of Neoprene Rubber

There are numerous formulations of Neoprene, each designed to meet particular performance standards. Neoprene is the material of choice for outdoor, maritime, and chemically exposed applications as compared to rubbers such as SBR.

Here are the main types of Neoprene:

Solid Neoprene Rubber

Gaskets, bushings, and vibration pads are made of this thick, resilient material. It offers excellent resistance to solvents, oils, and weather conditions.

Neoprene Foam (Closed-Cell)

Commonly used in wetsuits, medical braces, and insulation, this kind retains gas in tight pockets, delivering great water resistance, insulation, and buoyancy.

Open-Cell Neoprene

Open-cell Neoprene is a soft, breathable material used in various clothing items, as well as for padding and cushioning. Compared to closed-cell versions, it is less water-resistant but more flexible.

Neoprene Blends

Blends enhance qualities such as flexibility, softness, or cost-effectiveness by combining Neoprene with natural rubber or other synthetic materials. Frequently found in sporting equipment, automobiles, and fashion.

Advantages & Benefits of Neoprene

- Neoprene is unique because it can withstand tough environments when other rubbers can break down or malfunction. It is an excellent option for challenging situations due to its molecular structure, which provides a consistent blend of durability, chemical resistance, and insulation.

- Excellent resistance to oils, solvents, and heat

- Highly durable in outdoor and marine environments

- Flexible and compressible for cushioning applications

- Good thermal and moisture insulation

- Flame-retardant options are available.

- Resilient under high-stress and high-vibration scenarios

- Bonds well with adhesives and fabrics

- Long-lasting even under heavy mechanical wear

Applications of Neoprene

- Neoprene is utilized in various industries where flexibility, resistance, and durability are essential due to its well-rounded properties. Neoprene performs exceptionally well in corrosive, wet, and outdoor settings, whereas SBR is better suited for dry, high-friction settings.

- Wetsuits and diving gear

- Industrial gaskets, seals, and hoses

- Insulation for wires and electrical enclosures

- Protective gloves and safety gear

- Orthopedic braces and supports

- Automotive components (belts, bushings, vibration mounts)

- Marine equipment and dock bumpers

- Foam padding and soundproofing panels

- Laptop sleeves, bags, and neoprene fashion

- Construction joint fillers and roof membranes

What Is Neoprene Used For?

Neoprene is chosen for its exceptional chemical and weather resistance, making it an ideal material in industries that face harsh operating conditions.

Automotive Industry

Used in CV boots, belts, gaskets, and engine mounts due to its heat resistance and vibration-damping capabilities.

Construction

Employed in joint fillers, roofing sheets, and adhesives that withstand environmental stress and heavy loads.

Marine and Water Sports

Preferred for wetsuits, life jackets, and boat bumpers due to its water resistance, insulation, and flexibility.

Medical and Health

Used in orthopedic braces, gloves, and supports where comfort, hygiene, and elasticity are key.

Electrical and Electronics

Neoprene’s insulation properties make it ideal for cable jackets and housing that resist moisture and thermal shock.

Consumer and Fashion

From designer laptop sleeves to sports gear, Neoprene’s unique texture and stretch make it a favorite in functional fashion.

What Makes Neoprene Unique?

Neoprene holds a distinct place in the rubber family due to its unmatched durability, adaptability, and resistance to external elements, particularly in wet, chemically laden, or high-heat environments.

Superior Chemical & Oil Resistance

Performs consistently in contact with oils, greases, and industrial chemicals.

Enhanced FlexibWeather and UV Stabilityility & Elasticity

Ideal for long-term outdoor exposure without degradation.

Thermal Insulation & Fire Resistance

Naturally insulating and flame-retardant in many formulations.

Moisture Resistance

The closed-cell structure prevents water absorption, making it ideal for marine and water-based applications.

Adhesive & Fabric Compatibility

Easily laminated and bonded, widely used in composite materials.

Design Flexibility

Available in foams, sheets, and blends, enabling diverse product innovations.

Why Use Neoprene?

- For high-performance parts exposed to oils, heat, and environmental stress

- When weatherproofing and flame resistance are required

- In wet and humid conditions, where SBR and other rubbers fall short

- For durable, flexible cushioning in wearables and protective equipment

- When you need a long-lasting, resilient material that bonds well with fabrics or metals

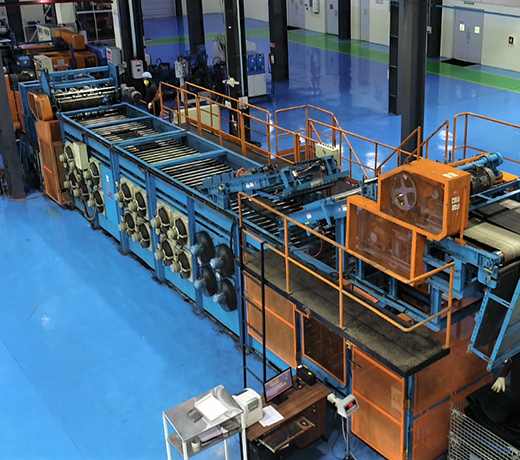

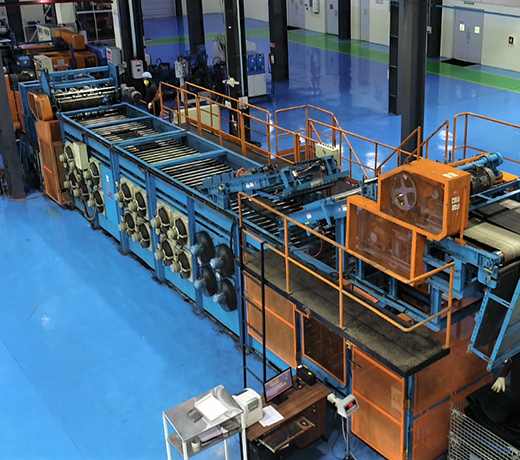

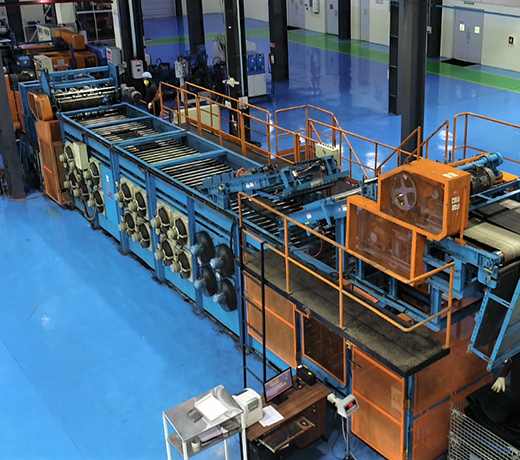

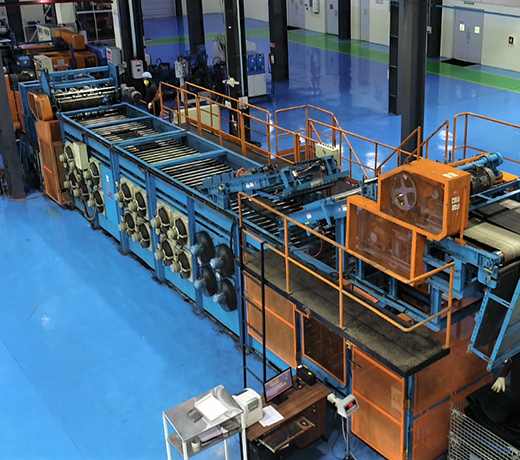

GB Gummi: Your Trusted Source for High-Performance Neoprene

- At GB Gummi, we don't just deliver rubber, we deliver performance you can count on. Our Neoprene solutions are tailored to meet your exact product requirements, ensuring both functionality and reliability. With rigorous quality control protocols in place, we maintain consistency across every batch. Our scalable supply chain enables timely and dependable deliveries, regardless of volume or destination. Backed by expert technical support, we guide you through every stage from selection to application.

- Our commitment to sustainability drives us to adopt eco-conscious manufacturing practices. At the same time, our in-house R&D team continually innovates to enhance material performance and meet the evolving demands of the industry.

FAQ's

1. What is neoprene used for?

Neoprene is a versatile synthetic rubber widely used in automotive, construction, marine, and consumer applications. It is commonly applied in hoses, gaskets, seals, protective gear, wetsuits, and insulation materials due to its resistance to oil, weather, and ozone. GB Gummi manufactures high-quality neoprene compounds tailored to meet industry-specific requirements, ensuring durability and consistent performance across a wide range of demanding environments.

2. What are the main properties of Neoprene?

The main properties of neoprene include excellent resistance to oil, ozone, weathering, and moderate heat, along with good mechanical strength and flexibility. It also provides flame resistance and durability, making it suitable for automotive and industrial uses. GB Gummi formulates neoprene compounds that balance these properties, delivering reliable solutions for applications that require long-lasting performance in challenging conditions.

We Deliver Custom Rubber Compounds for Every Need

Contact Us For Professional Support And Guidance.