Manufacturing Process

Raw Material Store With FIFO System

- Isolated Carbon Store.

- Independent Stores for Polymer, Chemical, and Oil.

- End-to-end traceability ensured by Barcode System

Auto Chemical Weighing

- Auto Weighing is monitored by the RECIPE MANAGEMENT SYSTEM.

Auto Carbon Dosing System

- Automated Carbon Dosing System with 2-step weight verification.

Auto Oil Dosing System

- Automated Oil Dosing System with 2-step weight verification.

Internal Mixer – Rubmix K100 and Banbury BM80

- Identification via Barcodes.

- Cross-Verification of Input Weights.

- Linked to RECIPE MANAGEMENT SYSTEM.

- Intermeshing Rotor System with Hydraulic Ram & TCU Controls.

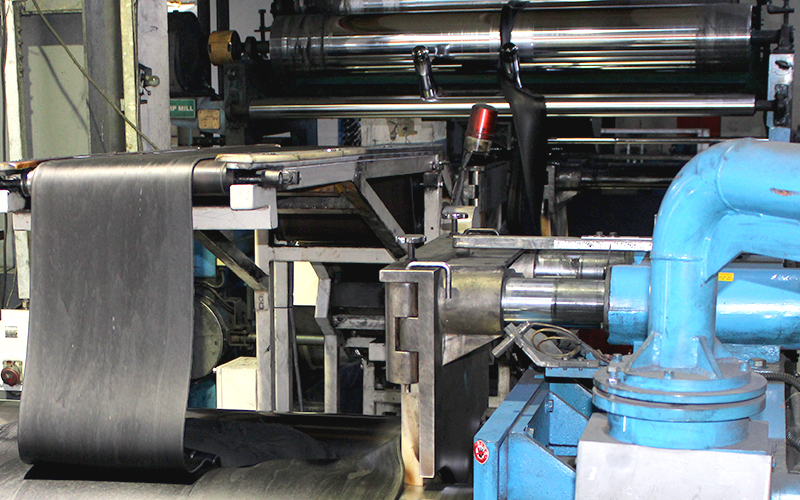

Open Mill With Stock Blender

- Metal Detector set up to identify impurities.

- 84″ Mill with Stock Blender ensures proper homogenization of the Rubber Compound.

- 72″ Mill & Batch Embossing Mechanism ensures the desired sheet or strip size as per customer-specific requirements.

Metal Detector Setup

- With our metal detector, we identify and eliminate any unwanted metal particles in the production process.

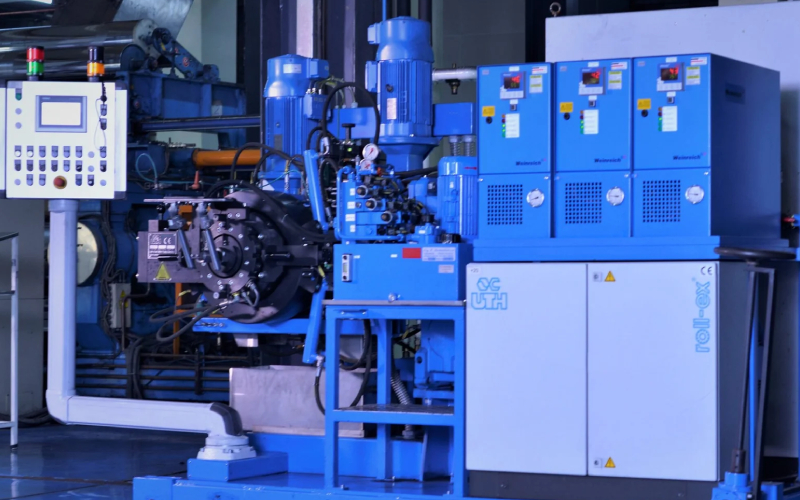

Gear Extruder With Strainer Head

- Rubber sheets ensure rubber compound purity for critical end applications.

Batch Off Cooling

- Cooling of the compound with tailored and precision-cut rubber sheets.

- Proper placement of the compound in the storage bin with wig-wag arrangement.

Research & Testing Lab

- TGA, DSC, and other testing equipment are utilized for R&D purposes.

- Material and physical tests are performed on RM and rubber compounds.

- Key tests include Rheological analysis, Carbon Dispersion monitoring, Tensile testing, and Elongation measurement.

Finished Goods Storage

- In-house COLD STORAGE facility with HUMIDITY CONTROLLER.

- Standard and customer-specific packaging solutions meeting international norms.

We Deliver Custom Rubber Compounds for Every Need

Contact Us For Professional Support And Guidance.