EPDM Rubber

Durable, Dependable, Designed to Last

Some materials are built for the short run, and some are built to last. EPDM rubber compound material belongs to the second group.

EPDM stands for Ethylene Propylene Diene Monomer. It’s a synthetic rubber that’s designed to perform under tough conditions. Not just for a few weeks. But for years. That’s why industries that deal with harsh weather, heat, steam, or chemicals often rely on it.

Whether you’re sealing a car door, covering a flat roof, or insulating an HVAC unit, the job needs more than just flexibility. It needs a material that resists cracking, shrinking, and degrading. That’s where EPDM rubber compound material steps in.

Let’s break down what EPDM is, how it works, and why it’s one of the most widely used synthetic rubbers in the world.

What Is EPDM Rubber?

- EPDM rubber compound material is a type of synthetic elastomer. It’s made from three monomers: ethylene, propylene, and a diene. These come together to create a structure that resists heat, weather, and aging. Unlike many rubbers, EPDM doesn’t get brittle over time. It stays flexible.

- In real terms, that means it doesn’t crack when the sun beats down on it. It doesn’t wear out when exposed to ozone or heavy rain. It doesn’t give up when stretched or bent. That’s why it’s trusted across construction, automotive, electrical, and mechanical sectors.

Key Properties of EPDM rubber compound material

Let’s look at the properties that make EPDM compound a standout choice across applications:

Weather resistance

EPDM resists UV rays, ozone, wind, and water. That’s why it performs well outdoors for years without losing shape or strength.

Temperature stability

It can tolerate temperatures from -40°C to 120°C. In some formulations, it can go even higher.

Chemical tolerance

EPDM shows good resistance to polar substances such as water, steam, alcohols, acids, and alkalis. However, it is not suitable for petroleum-based oils or solvents.

Electrical insulation

EPDM is non-conductive. That makes it ideal for cable jackets and insulation materials in electrical applications.

Elasticity

Even after compression, it returns to its original form. That makes it perfect for gaskets and seals that are under constant pressure.

Longevity

Its service life can often extend to 20 years or more, depending on environmental conditions and usage.

These properties make EPDM rubber a safe, reliable, and long-term material for a wide range of applications.

Where Is EPDM Used?

- You’ve probably interacted with EPDM material today without even realizing it. It’s in your car, your appliances, even in the building you’re sitting in.

- Here are common applications:

- Automotive Seals and Gaskets: Car doors, hoods, and windows rely on EPDM rubber to block dust, water, and wind. It keeps the cabin insulated and reduces noise.

- Roofing Membranes: Commercial buildings use EPDM roofing sheets because they’re lightweight, durable, and waterproof. Over 20 billion square feet of roofing in the US alone uses EPDM.

- HVAC Systems: It’s used to insulate pipes and seal joints. It improves energy efficiency and prevents leaks.

- Electrical Insulation: It acts as a protective layer around cables and enclosures.

- Industrial Tubing and Hoses: EPDM is used to manufacture flexible tubing for water, steam, and some chemicals.

- Construction Seals: Window and door frames use EPDM strips to prevent air and water infiltration.

EPDM vs Other Rubber Materials

When you’re selecting a rubber compound, options include Nitrile (NBR Rubber), Neoprene, Silicone, and Natural Rubber. Each has its strengths. However, when you require a material that performs well outdoors and withstands extreme temperatures or weather, EPDM rubber compound is the clear choice.

| Feature | EPDM | Natural Rubber | Neoprene | Nitrile |

|---|---|---|---|---|

| UV Resistance | Excellent | Poor | Good | Poor |

| Ozone Resistance | Excellent | Poor | Moderate | Poor |

| Water Resistance | Excellent | Moderate | Good | Excellent |

| Heat Tolerance | High | Low | Moderate | High |

| Chemical Resistance | Polar solvents | Low | Moderate | Oils and fuels |

| Cost | Low to moderate | Low | High | Moderate to high |

How to Choose the Right EPDM rubber compound material

Not all EPDM is the same. The right formulation depends on what you need it for. Thickness, hardness, density, and curing methods can all be customized.

Here are a few things to look at:

Application

Sealing, insulating, roofing, or vibration damping — each use may require a different grade.

Temperature range

Match the compound’s tolerance with your working environment.

Chemical exposure

While EPDM resists many chemicals, check if any non-polar substances are involved.

Shape and size

EPDM can be made into sheets, rolls, cords, profiles, or custom-molded parts.

Certifications

For critical industries like food, pharma, or automotive, always check for ASTM, ISO, or FDA-grade options.

Why GB Gummi Is Your Right EPDM Partner

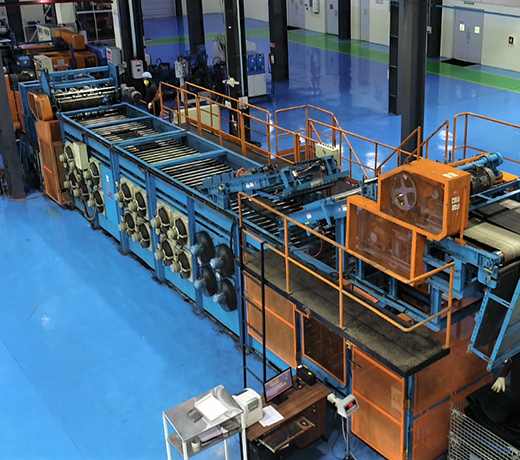

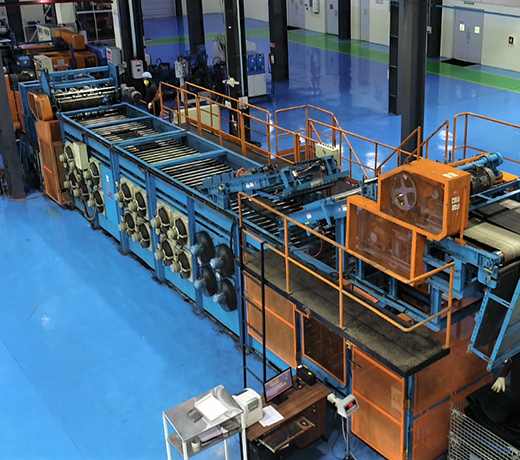

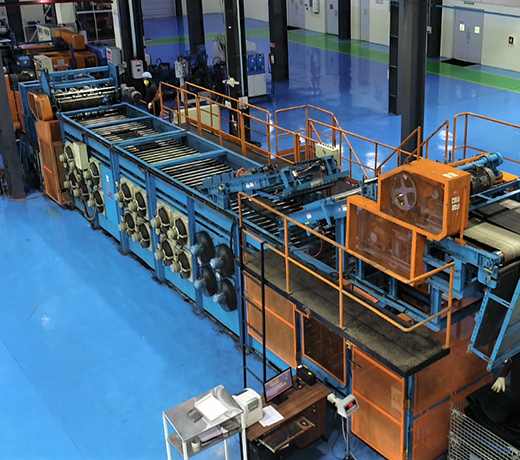

- At GB Gummi, we don’t just sell rubber. We build reliable compounds from scratch. Our team understands both the science and the application. We listen first, formulate second.

- What you get with us:

- Custom EPDM compounds for every need

- Fast turnaround times and scale-ready production

- Strict in-house quality control on every batch

- Clear documentation and traceability

- Technical advice and R&D support

- Whether you're an OEM, a processor, or a startup, we make sure your rubber performs in the field, not just in the spec sheet. If you’re looking for an EPDM rubber compound supplier that understands what your application truly needs, we’d be glad to help.

FAQ's

1. What is EPDM rubber compound?

EPDM rubber compound is a synthetic elastomer made from ethylene, propylene, and diene monomers. It is known for outstanding resistance to weathering, ozone, and high temperatures, making it ideal for outdoor and automotive uses. GB Gummi manufactures high-quality EPDM rubber compounds tailored to specific industry requirements, ensuring durability, flexibility, and long-lasting performance in demanding environments.

2. What is the purpose of EPDM rubber?

The main purpose of EPDM rubber is to provide excellent resistance to weather, heat, and UV exposure, making it suitable for outdoor sealing, insulation, and automotive applications. It is widely used in roofing, window seals, gaskets, and hoses. GB Gummi formulates their EPDM rubber compound that is designed to maintain performance over time, ensuring reliability even in challenging environmental conditions.

3. What are the common applications of an EPDM rubber compound?

EPDM rubber compound is commonly applied in automotive weather seals, hoses, gaskets, roofing membranes, and electrical insulation. Its resistance to ozone, water, and temperature extremes makes it highly versatile across industries. GB Gummi supplies tailored EPDM compounds that combine durability and flexibility, ensuring long service life and dependable performance for both industrial and consumer applications worldwide.

4. What are the main components of EPDM material?

EPDM material is made from ethylene, propylene, and a small amount of diene monomer. This unique composition gives it excellent flexibility, weather resistance, and durability. Fillers, curing agents, and additives are also used to enhance performance for specific applications. GB Gummi develops customized EPDM compounds using carefully selected components, ensuring consistent quality and reliability across automotive, industrial, and construction sectors.

5.What is EPDM material?

EPDM material is a synthetic rubber known for its outstanding resistance to ozone, UV rays, and extreme temperatures. It maintains flexibility and durability, making it suitable for long-term outdoor and industrial use. GB Gummi manufactures high-quality EPDM materials that meet international standards, offering tailored solutions for applications where weather resistance, sealing, and insulation are critical to performance.

6.Where is EPDM material commonly used?

EPDM material is commonly used in automotive weather seals, roofing membranes, gaskets, hoses, pond liners, and electrical insulation. Its ability to withstand heat, moisture, and harsh environmental conditions makes it a preferred choice across industries. GB Gummi supplies EPDM materials customized for these applications, ensuring long service life and reliable performance for customers in both domestic and international markets.

7.What are the benefits of EPDM rubber?

EPDM rubber offers excellent resistance to weather, ozone, UV rays, and extreme temperatures, making it ideal for outdoor and automotive applications. It also provides flexibility, durability, and water resistance, ensuring long service life. GB Gummi formulates EPDM rubber compounds that maximize these benefits, delivering high-performance solutions for industries requiring reliable sealing, insulation, and protection in harsh environments.

8. Is EPDM better than rubber?

EPDM rubber is a type of synthetic rubber that outperforms many general-purpose rubbers in weathering, ozone resistance, and temperature stability. While natural rubber provides superior elasticity, EPDM is better for outdoor and long-term applications. GB Gummi manufactures both natural and EPDM rubber compounds, helping industries choose the most suitable material based on specific performance needs and operating conditions.

9. What is EPDM rubber used for?

EPDM rubber is commonly used in automotive weather seals, roofing membranes, hoses, gaskets, and electrical insulation. Its ability to resist heat, water, and environmental stress makes it highly versatile across construction, automotive, and industrial applications. GB Gummi produces tailored EPDM rubber compounds designed to meet demanding performance standards, ensuring durability and reliability for customers worldwide.

11.What is EPDM suitable for?

EPDM is suitable for applications that demand resistance to weathering, ozone, UV rays, and extreme temperatures. It is widely used in automotive weather seals, roofing systems, gaskets, hoses, and electrical insulation. Thanks to its durability and versatility, EPDM is a preferred material across industries. GB Gummi manufactures high-quality compounds that deliver consistent performance, making them ideal for both industrial and consumer applications.

12. What are the limitations of EPDM compound?

While EPDM compound offers excellent resistance to weathering, ozone, and heat, it has some limitations. It is not suitable for applications involving oils, fuels, or strong solvents, as these can degrade its properties. In such cases, other elastomers like NBR may be better suited. GB Gummi helps industries select the right material by offering compounds tailored to specific needs while also providing alternative rubber solutions where required.

13. How are EPDM compounds processed and manufactured?

An EPDM compound is processed by blending base EPDM polymer with fillers, curing agents, and additives to enhance performance. The material is then mixed, shaped, and cured using either sulfur or peroxide systems, depending on the application. GB Gummi uses advanced compounding and mixing technologies to manufacture EPDM compounds, ensuring consistency, durability, and reliable performance across automotive, construction, and industrial applications.

We Deliver Custom Rubber Compounds for Every Need

Contact Us For Professional Support And Guidance.