Engineered for Excellence

NBR Nitrile Rubber That Delivers

At GB Gummi, we specialize in providing durable, versatile, and high-quality rubber solutions for industrial and commercial needs. One of our flagship materials is Nitrile Butadiene Rubber (NBR), a synthetic rubber known for its exceptional resistance to oil, fuel, and chemicals. Commonly referred to as nitrile rubber or NBR rubber, this material is engineered to meet the highest standards across multiple industries, from automotive to oil & gas.

With a reputation for combining flexibility, resilience, and sealing capabilities, nitrile rubber is the material of choice when oil resistance and wear strength are critical. Whether it’s seals, gaskets, or hoses, our NBR rubber delivers uncompromising performance in even the hardest environments.

Properties of Nitrile Butadiene Rubber

Nitrile Butadiene Rubber is a copolymer of butadiene and acrylonitrile, and its performance properties can be fine-tuned depending on the acrylonitrile content. The higher the acrylonitrile content, the better the oil resistance, but with a trade-off in flexibility.

Key properties include:

What are the Different Types of Nitrile Rubber?

General-Purpose NBR (Nitrile Butadiene Rubber)

This is the most widely used type of nitrile rubber, ideal for general sealing and gasketing needs. NBR nitrile in this form offers moderate resistance to oils, fuels, and chemicals, making it suitable for non-extreme environments. Its excellent flexibility, tensile strength, and cost-effectiveness make it a preferred material for O-rings, gaskets, and hoses across various industries.

Carboxylated NBR (XNBR)

A toughened version of standard NBR rubber, XNBR incorporates carboxylic acid groups into the polymer chain. This modification significantly boosts abrasion resistance, tensile strength, and tear resistance—while maintaining oil resistance. XNBR is commonly used in high-performance applications like dynamic seals, conveyor belts, and parts exposed to mechanical stress.

Hydrogenated NBR (HNBR)

HNBR is a chemically enhanced form of nitrile butadiene rubber, created through hydrogenation to reduce double bonds in the structure. This improves heat resistance, ozone stability, and aging performance. HNBR retains the oil and fuel compatibility of traditional, making it suitable for critical automotive parts (timing belts, hoses) as well as aerospace and industrial systems facing extreme conditions.

PVC/NBR Blends (Polyvinyl Chloride and Nitrile Rubber)

These blends with PVC to enhance flame resistance, chemical durability, and weather tolerance. The synergy of both materials results in versatile compounds used in fuel hoses, cable insulation, seals, and coatings, where fire safety and chemical strength are equally important.

Advantages & Benefits of NBR Nitrile

- Used widely in the automotive, oil & gas, and manufacturing sectors, NBR nitrile (or nitrile butadiene rubber) stands out due to its well-balanced performance properties. Here’s what makes it an ideal material for demanding environments:

- Superior oil and fuel resistance

- Good mechanical strength and flexibility

- Excellent wear and tear resistance

- Resistant to a wide range of chemicals

- Customizable for hardness, density, and temperature performance

- Cost-effective alternative to more expensive elastomers

- Performs well in dynamic and static sealing conditions

Applications of NBR Rubber

- NBR rubber is a versatile elastomer trusted across multiple industries for its outstanding oil resistance, mechanical strength, and temperature tolerance. From automotive engines to industrial machinery and even everyday consumer products, nitrile rubber plays a critical role in ensuring durability, safety, and performance under demanding conditions.

- Its adaptability to different formulations and environments makes it a go-to material in both static and dynamic applications.

- Automotive industry – fuel lines, gaskets, seals, and O-rings

- Oil and gas – hoses, blowout preventers, and pipeline seals

- Chemical plants – protective gloves, gaskets, and tubing

- Agriculture – hydraulic hoses and fuel system components

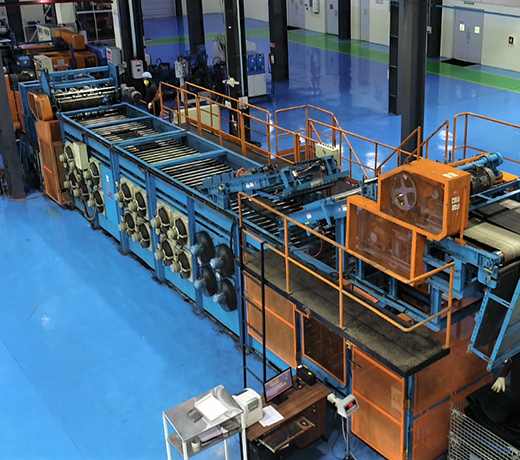

- Industrial manufacturing – rollers, conveyor belts, and diaphragms

- Personal protective equipment – chemical-resistant gloves

What is Nitrile Rubber Used For?

NBR is widely used in industries that require durable, oil-resistant materials. It is commonly found in:

Sealing applications

O-rings, gaskets, and washers

Automotive components

Timing belts, fuel system parts, and seals

Protective gear

Disposable and reusable nitrile gloves for chemical handling

Machinery and tools

Hoses, diaphragms, and mats

What Makes Nitrile Rubber (NBR) Unique?

- What sets NBR apart is its superior compatibility with oils and fuels, which natural rubber lacks. Its structure allows for chemical bonding with hydrocarbons, providing unmatched resistance in fluid transfer applications. Moreover, it offers a balance between performance and affordability, making it ideal for both OEMs and aftermarket solutions.

Why use Nitrile Rubber?

- Industries choose nitrile rubber not just for its chemical resistance, but for its proven reliability in the field. Whether it's heavy-duty machinery or complex fluid systems, NBR rubber delivers consistent performance over time—reducing downtime, enhancing operational efficiency, and aligning with modern sustainability goals.

- Long-lasting performance in challenging environments

- Lower maintenance costs due to its durability

- Reliable sealing and mechanical support

- Compatibility with existing systems and manufacturing processes

- An eco-conscious and sustainable solution with recyclable options

Why Choose GB Gummi for NBR Rubber?

Whether you’re upgrading existing systems or sourcing rubber components for a new project, GB Gummi is your trusted partner for high-performance NBR nitrile rubber solutions. Our team is here to help you choose the right formulation—be it standard nitrile butadiene rubber, XNBR, HNBR, or PVC/NBR blends—tailored to your specific industry needs.

Have questions or need a custom solution?

Reach out to our expert team today for technical guidance, material selection, or bulk orders. Let’s create rubber products that are engineered for strength, built for endurance, and designed to perform.

Contact us now to learn more or request a quote—because at GB Gummi, your performance is our priority.

FAQ's

1. What is Nitrile Butadiene Rubber (NBR)?

Nitrile Butadiene Rubber (NBR) is a synthetic elastomer created by polymerizing acrylonitrile and butadiene. It is highly valued for its resistance to oils, fuels, and chemicals, making it more durable than many natural rubbers. GB Gummi produces high-quality NBR compounds tailored for diverse applications, ensuring consistent performance in industries that demand strength, flexibility, and resistance to harsh operating environments.

2. What is Nitrile Butadiene Rubber used for?

Nitrile Butadiene Rubber is widely used in applications that require resistance to oil, fuel, and chemicals. It is commonly applied in seals, gaskets, hoses, O-rings, and fuel system components. GB Gummi formulates specialized NBR compounds designed to withstand demanding conditions, ensuring reliability in automotive, industrial, and mechanical applications where both durability and flexibility are essential for long-term performance.

3. What industries typically use Nitrile Butadiene Rubber (NBR)?

Industries that rely on Nitrile Butadiene Rubber (NBR) include automotive, oil and gas, aerospace, industrial machinery, and medical equipment. Its unique combination of resistance to oils, chemicals, and abrasion makes it a preferred choice for seals, hoses, and protective components. GB Gummi, as a trusted compounder, supplies tailored NBR solutions that meet the stringent requirements of these industries, ensuring quality and reliability across multiple sectors.

4. What are the key properties of Nitrile Butadiene Rubber (NBR)?

The key properties of Nitrile Butadiene Rubber (NBR) include excellent resistance to oils, fuels, and solvents, along with good abrasion resistance and flexibility. NBR also performs well in a wide temperature range, making it suitable for harsh operating conditions. GB Gummi develops high-performance NBR compounds that balance durability with elasticity, offering reliable solutions for industries that demand superior mechanical and chemical resistance.

5. What is nitrile rubber used for?

Nitrile rubber, also known as NBR, is primarily used in applications that demand resistance to oils, fuels, and chemicals. It is commonly found in automotive fuel hoses, seals, O-rings, gaskets, gloves, and industrial products. GB Gummi develops specialized nitrile rubber compounds that combine durability with flexibility, making them ideal for industries requiring long-lasting materials that can withstand exposure to harsh fluids and demanding environments.

6. Which is better, NBR or EPDM?

The choice between nitrile rubber (NBR) and EPDM depends on application needs. NBR offers excellent oil and fuel resistance, making it ideal for automotive and industrial uses. EPDM, on the other hand, performs better in outdoor and high-temperature environments due to its resistance to weathering and ozone. GB Gummi manufactures both nitrile and EPDM compounds, helping clients select the best option based on specific performance and durability requirements.

7. What is NBR nitrile?

NBR nitrile, short for Nitrile Butadiene Rubber, is a synthetic elastomer made from acrylonitrile and butadiene. It is widely recognized for its resistance to oils, fuels, and many chemicals, making it a reliable alternative to natural rubber in demanding conditions. GB Gummi formulates high-quality NBR nitrile compounds tailored for automotive, industrial, and sealing applications, ensuring durability, flexibility, and long-lasting performance.

8. What are common products made from NBR nitrile?

Common products made from NBR nitrile include fuel hoses, gaskets, seals, O-rings, gloves, and conveyor belts. Its unique resistance to oil, abrasion, and solvents makes it especially valuable in automotive, aerospace, and industrial machinery applications. GB Gummi specializes in producing customized NBR nitrile compounds that meet specific performance requirements, ensuring reliable solutions for manufacturers across diverse sectors worldwide.

9. Who are the leading NBR rubber manufacturers in India?

India is home to several NBR rubber manufacturers known for producing high-quality compounds for global markets. GB Gummi stands out as one of the leading names, offering advanced compounding technology, global certifications, and customized solutions. Their NBR rubber products are trusted by automotive, industrial, and engineering companies worldwide, thanks to consistent quality, innovation, and the ability to meet international performance standards.

10. What are the common applications of NBR rubber?

NBR rubber is widely used in applications that demand resistance to oils, fuels, and chemicals. Common applications include automotive fuel hoses, seals, O-rings, gaskets, gloves, and industrial machinery components. GB Gummi supplies tailored NBR rubber compounds that ensure durability and flexibility, making them suitable for industries where reliability and resistance to harsh operating environments are critical.

We Deliver Custom Rubber Compounds for Every Need

Contact Us For Professional Support And Guidance.